Because the designs we create are flexible, we can quickly respond to changing customer requirements. Model-Based Design with MATLAB and Simulink has enabled us to evaluate many design ideas for each project.

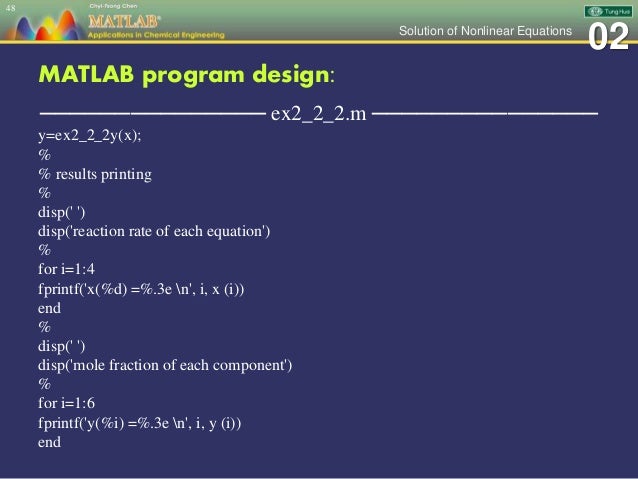

Matlab for chemical engineering code#

Our process engineers can use the blocks by simply dragging and dropping them into the Simulink environment, but they can also study the underlying MATLAB code and develop new MATLAB classes, as well as create new libraries in Simulink.

The outputs of the absorption tower model, one gas object and one fluid object, capture the results and are used as input to the next subsystem in the plant. The classes perform all the operations that were previously done in spreadsheets, as well as several new calculations that were enabled by the switch to MATLAB-for example, calculation of the heat generated by the absorption of SO3 in different concentrations of sulfuric acid. We modeled the thermodynamic and kinetic processes in MATLAB using the classes we had developed. In the actual tower, the gas enters at the bottom of a column and is partially absorbed by the liquid, which enters through the top of the tower and runs down through the column. To manage the overall complexity of our designs, we defined each module as a MATLAB class, enabling us to apply object-oriented design patterns to the development of the entire library.Īn absorption tower, for example, is defined as a MATLAB class, as are the fluid and gas streams that it takes as input. The first step in the new workflow was to create a library of reusable modules, one for each subsystem, which the chemical process engineers could then combine in Simulink system models. The new approach is 5 to 10 times faster than the spreadsheet-based approach, and much less susceptible to human error. The plant and its control system can then be tested in dynamic and steady-state closed-loop simulations. While the chemical process engineers model the complex thermodynamic and kinetic interactions within the plant, controls engineers model the control algorithms.

Model-Based Design with MATLAB ® and Simulink ® has provided a cost-effective way to simplify and automate our design workflow by enabling chemical process engineers and controls engineers to work in the same environment.

Matlab for chemical engineering manual#

This manual approach slowed development and introduced the potential for human error. All preliminary design work and process modeling was done using a complex system of spreadsheets. Until recently, however, our development process was highly labor-intensive. HUGO PETERSEN GmbH has a decades-long track record of engineering safe and efficient sulfuric acid and gas cleaning plants. Used acid and waste gases are recycled in processing plants that must meet stringent safety and environmental requirements for working with these chemicals. Sulfuric acid is used in the manufacture of fertilizers, petrochemical products, synthetic fiber, steel, and a wide range of other industrial materials.

0 kommentar(er)

0 kommentar(er)